Article

Article

Hoshin Kanri is effective strategy deployment without a bureaucratic air but with a commitment to continuous improvement. Elliott Weiss and Austin English describe the simple construct that increases engagement at all levels, detailing general concepts, basic steps, and keys to successful implementation and iteration.

Hoshin Kanri is effective strategy deployment without a bureaucratic air but with a commitment to continuous improvement. Elliott Weiss and Austin English describe the simple construct that increases engagement at all levels, detailing general concepts, basic steps, and keys to successful implementation and iteration.

Hoshin kanri (HK),1 or strategy deployment, has been an integral part of the company management practices of some of the most successful Lean-practicing organizations. Done well, it is an extraordinary tool to help a team develop, adjust and communicate strategy to meet robust, long-term goals. Hoshin (loosely translated as policy, plan, purpose or target) is meant to encompass strategic alignment across the organization. The organization can be as large as the entire company or a small as an individual value stream. Kanri (loosely translated as control or management) is meant to indicate that this management tool is a disciplined manner of continuous improvement execution. Hoshin can be thought of as the skeleton that holds the strategy together, while kanri can be thought of as the muscle that performs the task. Both must be exercised in order to have and maintain a strong body. Most importantly, HK must be grounded at gemba,2 intent on creating customer value, and built around continuous improvement. It should not take on a bureaucratic air of driving strategy.

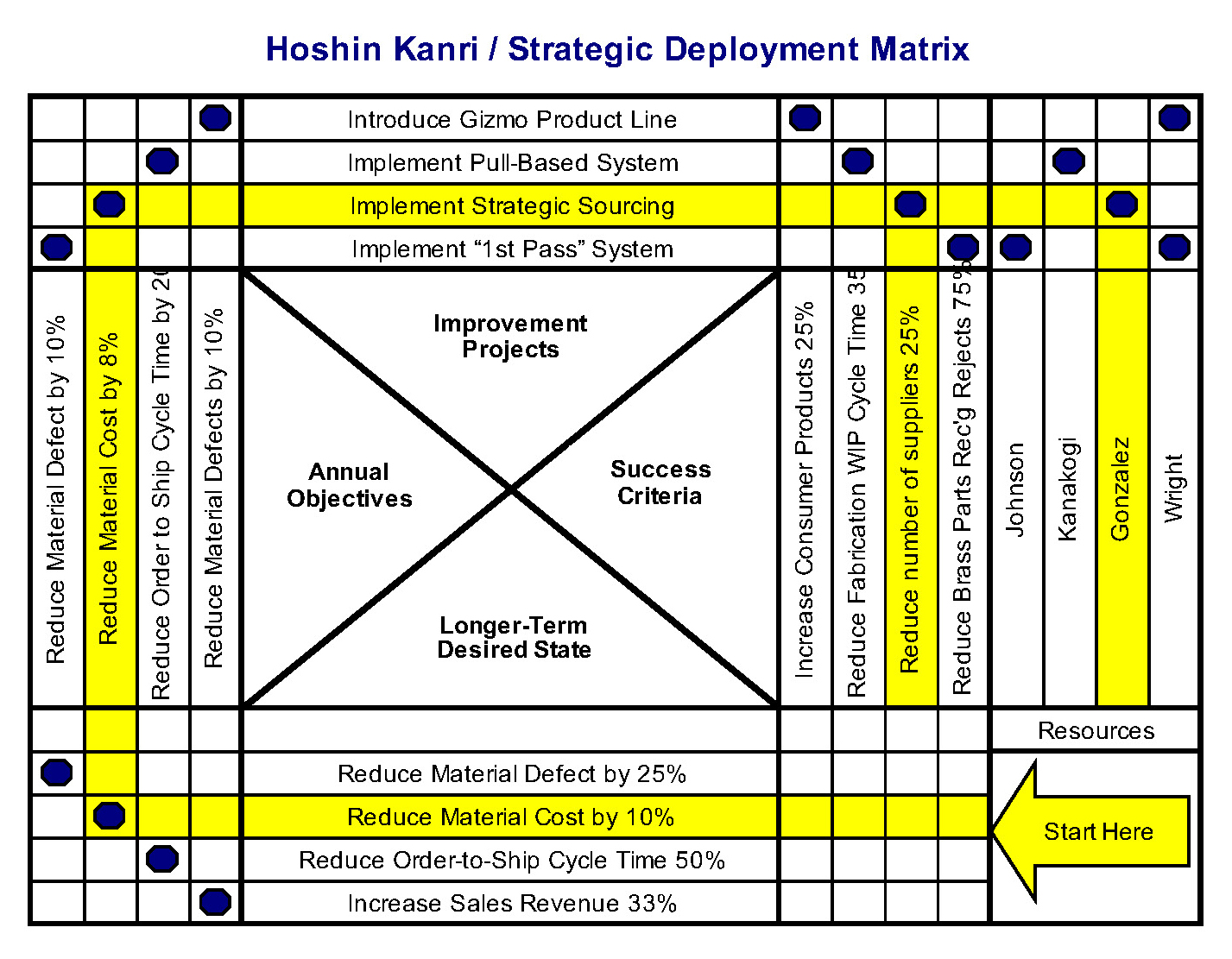

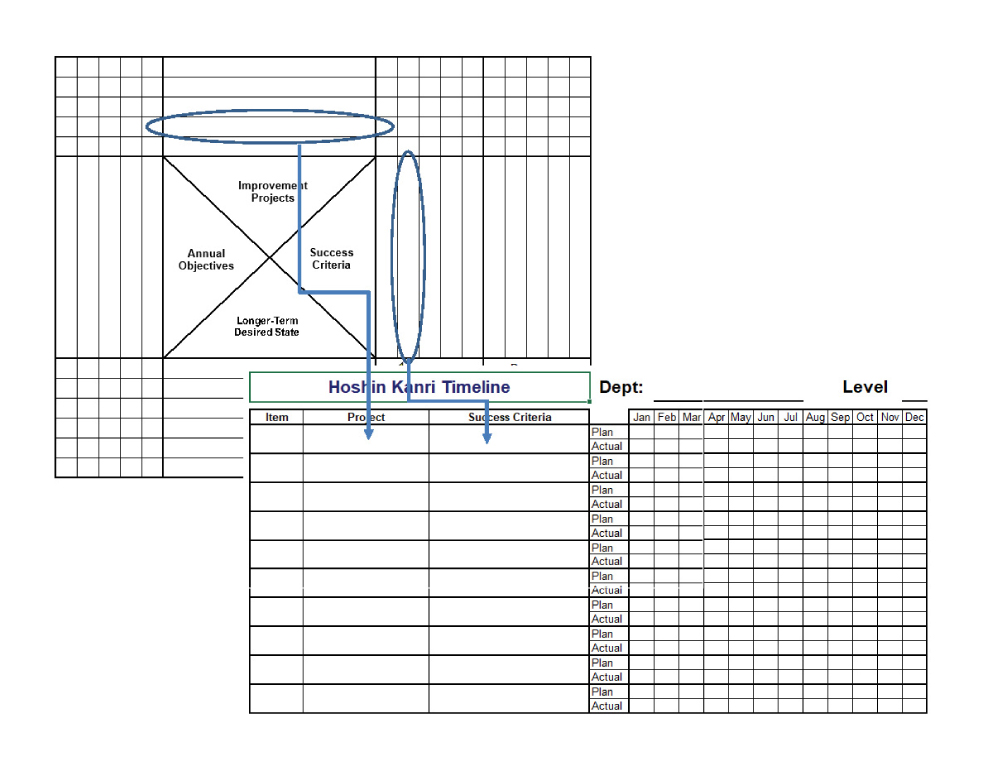

One of the keys to HK’s success is its simple, easy-to-understand construct. Fundamentally, a few pages help develop and communicate what the long-term goals are and how the value stream plans on accomplishing them, as well as who the responsible leader is and how progress will be measured. Done well, this will end with more engagement, ownership and accountability from all levels of the organization.

The value of keeping it simple includes the ability to engage individuals at all levels of the organization. The simple fact that more people understand what the organization is trying to achieve, how individuals’ activities affect these actions and why their activities are important goes a long way toward creating constructive engagement in many more associates.

After creating your value stream’s HK matrix and timeline, use it as a grounding point for all relevant conversations with all associates and leadership up and down the value stream chain of command. It is a living document. Debate, assimilate and adjust as necessary. The most successful value streams use this in their staff meetings and daily huddles to remind everyone of the continuous-improvement priorities. This is especially important as you test your resolve against the daily firefights and setbacks and the knee-jerk tendency to start a new project or abort one. As boxer Mike Tyson once said, “Everybody has a plan until they get punched in the mouth.”4 The work put into creating and maintaining a living hoshin kanri plan can keep reminding the whole team of the plan they know will ultimately win the fight.

The preceding is excerpted from the technical note A Brief Note on Hoshin Kanri: Strategy Deployment (Darden Business Publishing) by Darden Professor Elliott N. Weiss and Visiting Executive Lecturer Austin English.

Weiss is a top authority in many aspects of manufacturing, including inventory control, manufacturing planning and scheduling, manufacturing project management, materials management, service industry operations, total productive maintenance and lean systems.

Weiss is the author of numerous articles in the areas of production management and operations research and has extensive consulting experience for both manufacturing and service companies in the areas of production scheduling, workflow management, logistics, lean conversions and total productive maintenance.

B.S., B.A., MBA, Ph.D., University of Pennsylvania

Hoshin Kanri: A Management Tool for Continuous Improvement

Share